Single Disc Dryer

The Dryer One™ “Single Disc” dryer is an ideal solution for operations with lower production capacities (compared to the “Double Disc” model), for drying processes using lower-temperature air, and in cases where the amount of moisture to be evaporated is relatively small. It is especially well-suited for input materials with lower initial moisture content, as well as for applications that require gentle drying at lower temperatures.

The material is spread across a rotating disc, which is exposed to a flow of hot air (ranging from 122°F to 212°F) supplied by an external low-temperature energy source, such as a cogeneration unit or a boiler.

A key feature of the “Single Disc” dryer is its ability to recycle the air that has passed through the product at the end of the drying cycle—air that remains both warm and dry—by redirecting it back to the start of the process to pre-dry the incoming material. This significantly enhances the system’s overall energy efficiency.

Once it passes through the material layer, the saturated and cooler exhaust air—typically between 77°F and 86°F—is released through the central stack.

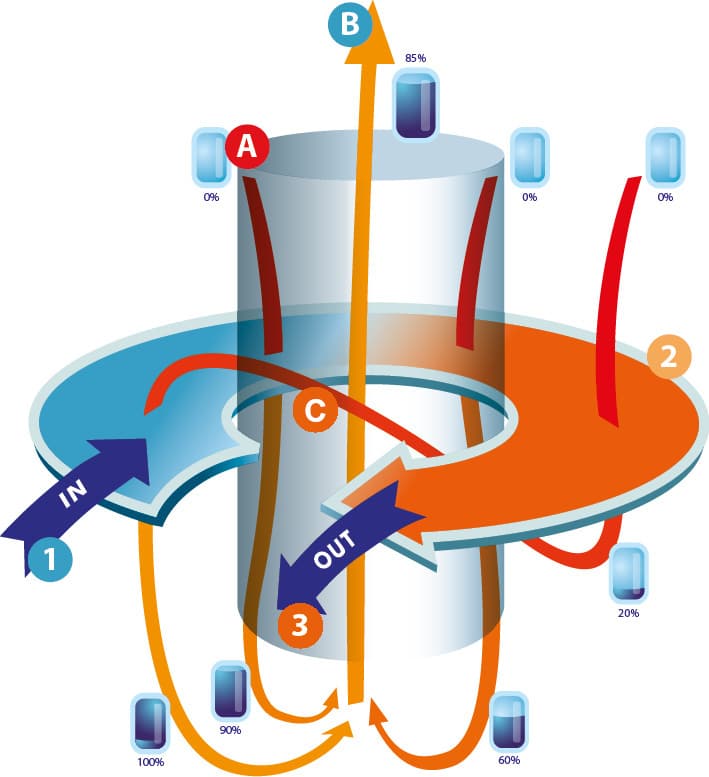

| IN The rotating platform is supplied with material to be dried. |

|

| DRYING The material to be dried rotates 360° on the rotating platform. |

|

| OUT The dried material is discharged to the packaging or storage area. |

|

| HOT AIR INLET Hot air is drawn from top to bottom through the platform. |

|

| EXTRACTION & EXPULSION OF MOISTURE-SATURATED AIR The moisture-saturated air is pulsed upward to be expelled. Any dust can be filtered. |

|

| ENERGY RECOVERY SYSTEM Excess energy available at the end of the drying cycle can be recovered using a recirculation fan and reused at the beginning of the cycle, where the wettest product is located. |

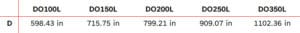

Single Disc Range

*Example of wood shavings drying at a 10% moisture content rate. These values are indicative and may vary depending on the nature of the product and the drying conditions.

The material layer is passed through by a flow of hot air. Subsequently, the used air, saturated with water and cooled to a temperature of 77 to 86°F, is expelled through the central chimney.

To optimize the energy performance of the device, the “single disc” dryer can optionally be equipped with an energy recovery system, allowing excess energy from the “dry” zone to be captured and reused in the “wet” zone.

In addition, the outer casing of the dryer is fully insulated.

Low-temperature dried materials generate extremely low levels of pollutant particles.

An integrated fire detection and extinguishing system, combined with the use of primarily non-flammable materials that prevent the spread of fire, makes the Dryer One™ a piece of equipment with an extremely low fire risk, enhancing the safety of the production site.

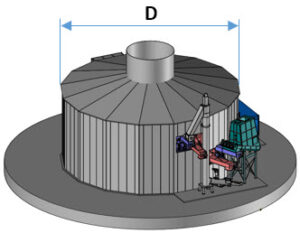

The circular shape of the Dryer One™ minimizes its footprint, allowing easier integration into existing production sites.

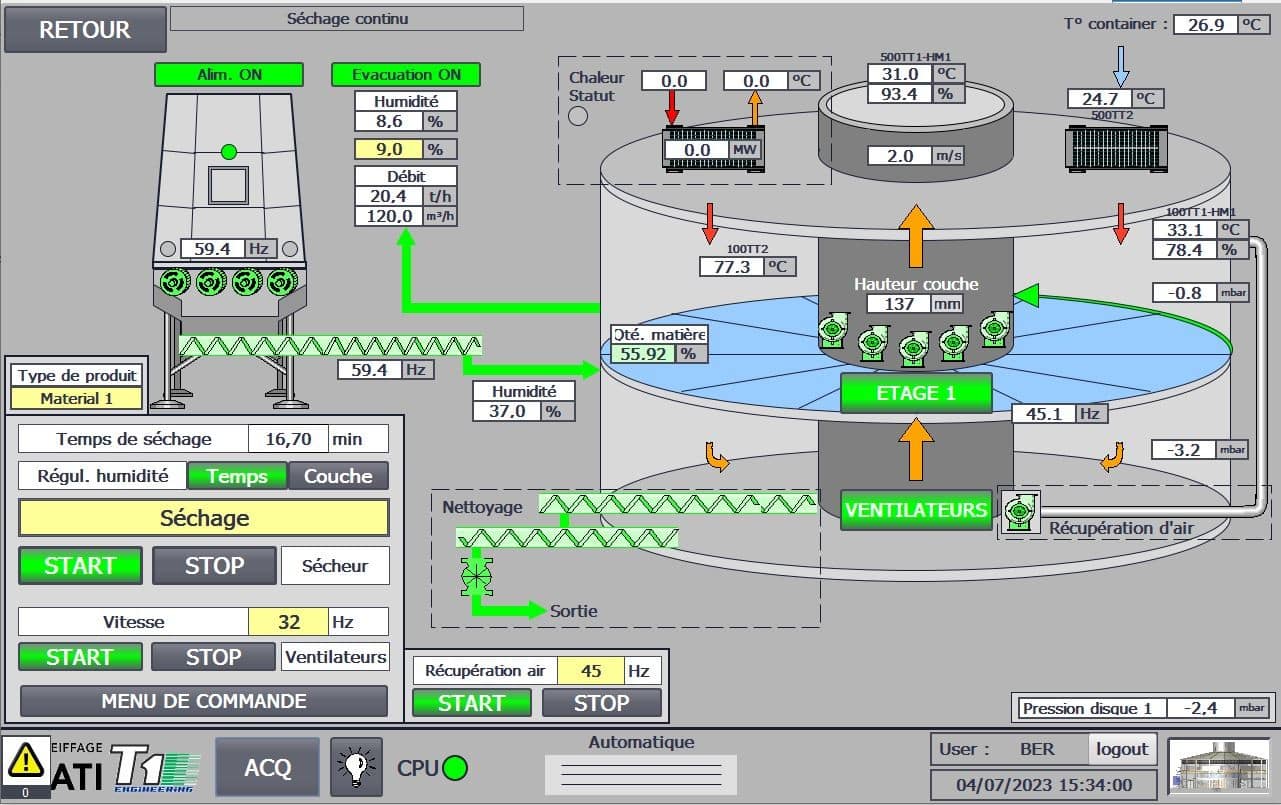

The advanced automation system of Dryer One™ optimizes efficiency, precision, and safety. Fully automated, it requires minimal operator supervision, ensures precise control of the moisture content, and enables the generation of production reports.

Dryer One™ dryers are compatible with various low-temperature heat sources, such as hot water, hot air, or steam, produced by biomass boilers, natural gas burners, or cogeneration installations.